Mining Industries

| Charter |

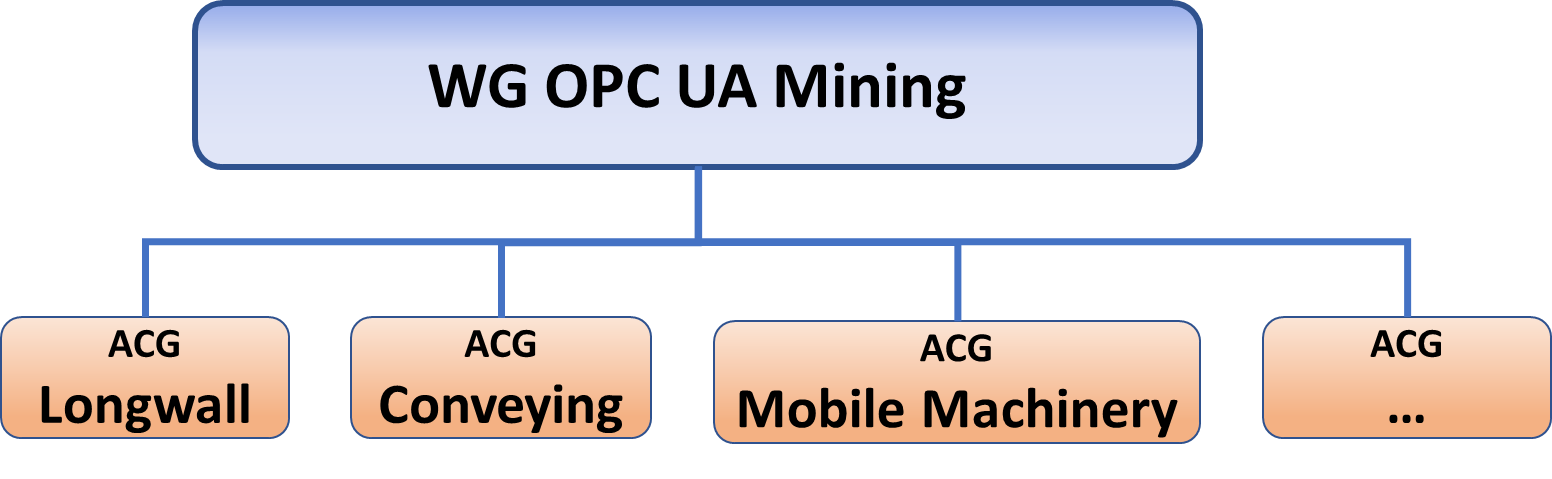

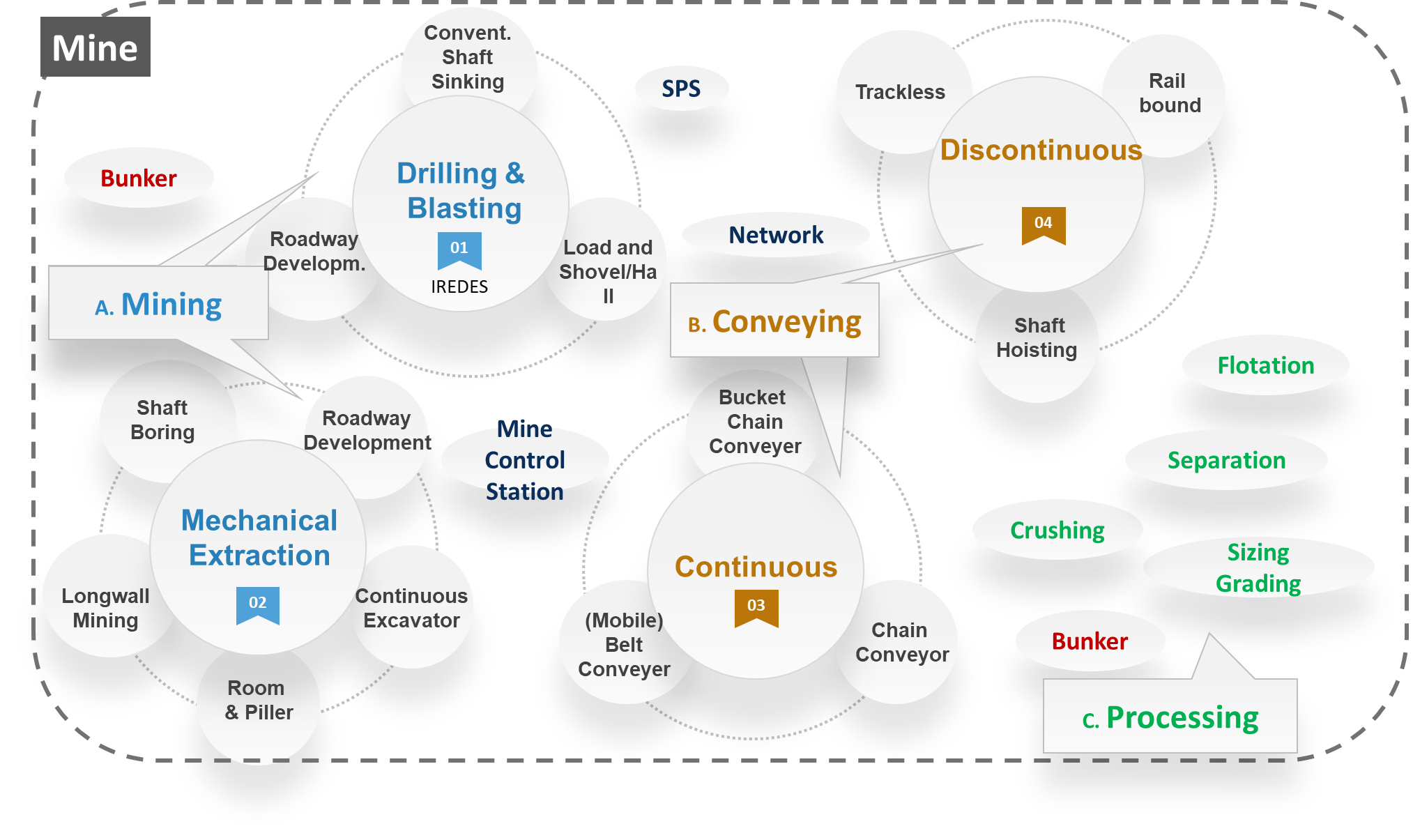

Scope / GoalsDevelop specifications for the different processes in mining and vertically into higher level mine operation systems for control, information and diagnostic purposes. The basic description of the mining machinery and equipment is supplemented by selected use cases, e. g. longwall conveying, mobile mining machineries and mine operations. Structure WG and ACG The structure of the VDMA OPC UA mining Initiative is divided into the Working Group (WG) and the Application Case Group (ACG)  ScopeThe OPC UA Companion Specification Mining includes a basic description of the mining machineries and equipment. Main scope is to support the machine to machine communication in the different processes in mining and vertically into higher level mine operation systems for control, information and diagnostic purposes. The basic description of the mining machinery and equipment is supplemented by selected use cases, e. g. longwall conveying, mobile mining machineries and mine operations.  Technical AspectsMining faces the challenge that how the processes can be implemented depends on the mine, machinery, geology and raw material. For this reason, the first two specialist groups dealt with the development of use cases for mobile machines and highly automated longwall mining. Particular emphasis was placed on ensuring that implementation for mine operators or system integrators is as simple as possible and that content that is not required does not have to be implemented.  OPC UA 40560 Mining General provides general information on the use of the Companion Specifications to make it easy to get started. In OPC UA 40569 “Application/Use Cases”, the use cases are listed with the machines and systems involved and displayed graphically to make implementation as easy as possible. Sequence diagrams are provided for the user to illustrate the use case and communication between the individual machines and systems. Conveying: The “Conveying” specialist group brings together companies from manufacturers of conveyors, idlers, scrapers, belt scales and belts. A total of 19 use cases have been developed, 10 of which are expected to be published within 2025 and the rest in 2026.  Processing: The “Processing” specialist group consists of experts from mobile processing machine companies, stationary systems and solution providers. Due to the different machines and processes, the existing companion specifications were first reviewed and checked to see what information can already be provided and used by machines. The information provided by the individual processing machines was then identified and categorized. In the next steps, use cases and the exchange of information between the machines themselves or with higher-level systems will be developed on this basis. In addition to this work, cooperation with SENAI (Serviço Nacional de Aprendizagem Industrial) in Brazil was initiated in order to gain the cooperation of mine operators. Brazil: Together with SENAI, the VDMA has set up a specialist group to work with manufacturers and operators in Brazil to develop use cases for conveyor belt systems and processing. SENAI has a demonstrator that simulates a processing plant. Various components and systems from different manufacturers are installed here to demonstrate the data exchange between the different components for controlling the process. A regular exchange with the group has been established to ensure that the results are incorporated into the Companion Specifications Mining. More Information |

|

| Working Group Type | Joint | Status: Active |

| Partner Organisation(s) | VDMA Mining; IREDES ("International Rock Excavation Data Exchange Standard") | |

| Partner Logo(s) |  |

|

| Classification(s) | Oil and Gas, Mining | |

| Chair(s) | Joern Lehmann | |

| Marketing URL | https://opcfoundation.org/markets-collaboration/mining/ | |

go back

go back